What is Machined Delrin: Understanding Its Unique Properties and Uses

What is Delrin? Delrin, also known as POM (Polyoxymethylene), is a high-performance plastic recognized for its exceptional mechanical properties, making it a preferred choice in engineering and manufacturing. This article explores the answer to the question “what is Delrin?”, its unique properties, and its applications, demonstrating why it is a favorite among engineers and manufacturers.

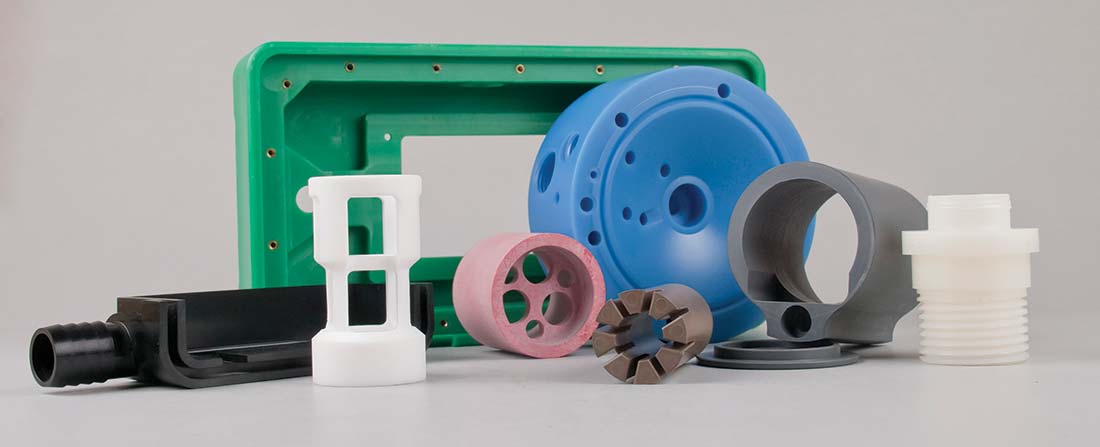

Delrin’s mechanical properties make it an ideal choice for applications demanding durability and precision. With a mix of strength, flexibility, and easy machinability, Delrin has built a strong reputation for producing a wide range of components.

What Is Delrin? An Overview of Its Composition

Delrin is a type of acetal resin, primarily made of polyoxymethylene, a polymer derived from formaldehyde. Its chemical structure features repeating methylene units, which contribute to Delrin’s strength and rigidity. This composition gives Delrin its unique characteristics, making it suitable for many applications.

The Manufacturing Process of Delrin

Producing Delrin involves a process called polymerization, in which formaldehyde transforms into a solid polymer. This process can be controlled to achieve different molecular weights, affecting the final product’s properties. Manufacturers can process the resulting resin using methods like injection molding and extrusion, enabling them to create complex shapes and parts.

Types of Delrin Plastic

Delrin plastic comes in several grades, each designed for specific applications. Some common grades include:

- Delrin 100ST: Known for its excellent wear resistance and low friction, ideal for gears and bearings.

- Delrin 150: Offers a balance of strength and toughness, suitable for various applications.

- Delrin AF: Contains solid lubricant additives, enhancing wear resistance even further.

Understanding the different grades of Delrin helps you choose the right type for your project.

Unique Properties of Delrin: Strength and Flexibility

Delrin’s standout feature is its unique mix of strength and flexibility. This balance makes it a versatile material for various applications.

Define Delrin And It’s Mechanical Strength

Define delrin: It boasts high tensile strength, allowing it to endure heavy loads without deforming. Its tensile strength ranges from 70 to 90 MPa, depending on the grade. This property is vital in applications where mechanical integrity is crucial, such as automotive and industrial components.

Flexural Modulus

Delrin also has a high flexural modulus, meaning it resists bending under stress. This property is essential for components that need to maintain their shape while facing forces.

Chemical Resistance

Delrin resists various chemicals, including solvents, oils, and fuels. This resistance makes it suitable for harsh environments, ensuring longevity and reliability.

Temperature Stability

Delrin performs well across a wide temperature range, typically from -40°C to 100°C. This temperature stability allows it to be used in applications with significant temperature fluctuations.

Comparing Delrin with Other Plastics: Pros and Cons

When choosing Delrin for your project, it’s helpful to compare it with other plastics to understand its benefits and drawbacks.

| Pros of Delrin | Cons of Delrin |

| High strength-to-weight ratio: Delrin provides strong performance while remaining lightweight, making it perfect for weight-sensitive applications. | Cost: Delrin often costs more than other plastics, which may be a concern for budget-conscious projects. |

| Ease of machining: Delrin machines easily into complex shapes with high precision, reducing production costs and time. | UV sensitivity: Delrin can degrade under prolonged UV exposure, making it less suitable for outdoor applications without treatment. |

| Low friction: Its low coefficient of friction makes Delrin ideal for gears and bearings, where smooth operation is vital. | Limited color options: Typically available in natural and black, which may not meet aesthetic needs for some applications. |

Key Applications of Delrin in Various Industries

Delrin’s unique properties lend themselves to various applications across multiple industries. Here are some notable uses:

Automotive Industry

In automotive manufacturing, Delrin serves in components like gears, bearings, and fuel system parts due to its strength and chemical resistance. Its low friction properties enhance the efficiency of moving parts.

Electronics

Delrin finds use in electronic devices for components needing durability and precision. Its insulating properties make it an excellent choice for housings and connectors.

Medical Devices

In the medical field, Delrin is used to produce components that can withstand sterilization. Its biocompatibility and chemical resistance make it suitable for various medical applications.

Consumer Products

Delrin appears in numerous consumer products, from kitchen appliances to sporting goods. Its versatility allows manufacturers to create durable and functional designs.

Delrin in Manufacturing: Benefits for Production Processes

Using Delrin in manufacturing offers several advantages that can boost productivity and product quality.

High-Volume Production

Delrin can undergo injection molding, allowing high-volume production of parts with consistent quality. This efficiency benefits manufacturers aiming to scale production while maintaining standards.

Customization

Manufacturers can easily customize Delrin parts to meet specific design requirements. With various grades available, selecting the right Delrin type for desired properties becomes straightforward.

Reduced Assembly Time

Delrin’s versatility and ease of machining often lead to fewer components in an assembly, cutting down assembly time and costs. This benefit is crucial in industries where efficiency matters.

How to Choose the Right Grade of Delrin for Your Project

Selecting the right Delrin grade is critical for meeting your application’s needs. Consider these factors:

Application Requirements

Assess your application’s demands, including load-bearing capacity, environmental conditions, and required durability. This evaluation helps identify which Delrin grade suits your needs best.

Machining Needs

Think about the complexity of the parts you need to manufacture. Some Delrin grades are easier to machine than others, so choose one that matches your machining capabilities.

Cost Considerations

While Delrin is a high-performance plastic, it can be pricier than other materials. Ensure the benefits of using Delrin justify the costs for your specific project.

Caring for Delrin Products: Maintenance Tips and Best Practices

Though Delrin is durable, proper care and maintenance can extend the lifespan of Delrin products. Here are some best practices:

Cleaning

Clean Delrin products with mild soap and water. Avoid abrasive cleaners that might scratch the surface. For tougher stains, a soft cloth with diluted vinegar works well.

Storage

Store Delrin products in a cool, dry place away from direct sunlight to prevent UV degradation. If possible, keep them in protective covering to avoid scratches.

Regular Inspections

Regularly inspect Delrin products for signs of wear or damage. Early detection prevents more significant issues later.

Innovative Uses for Delrin You Might Not Know About

Delrin continues to inspire innovative applications across various fields. Here are some lesser-known uses that highlight its versatility:

3D Printing

Advancements in 3D printing technology increasingly incorporate Delrin as a material for additive manufacturing. Its mechanical properties make it suitable for creating strong and functional prototypes.

Musical Instruments

Delrin plays a role in producing components for musical instruments, such as mouthpieces for woodwind instruments. Its durability and moisture resistance make it a preferred choice for musicians.

Robotics

Delrin’s low friction properties suit robotic components, allowing smooth movement and precise control. Its strength ensures robotic parts endure rigorous use.

Aerospace

In aerospace, Delrin serves in parts requiring high strength and low weight. Its performance in extreme conditions makes it valuable for aircraft components.

| Property/Aspect | Description | Applications/Implications |

| High Strength | Delrin has a tensile strength ranging from 70 to 90 MPa, making it robust for heavy loads. | Ideal for automotive parts, industrial machinery, and structural components. |

| Flexibility | Balances strength with flexibility, allowing it to endure stress without breaking. | Suitable for gears, bearings, and components that face dynamic forces. |

| Chemical Resistance | Resists solvents, oils, and fuels, ensuring reliability in harsh environments. | Utilized in automotive fuel systems, industrial equipment, and medical devices. |

| Temperature Stability | Performs well between -40°C to 100°C, maintaining integrity across various temperatures. | Applicable in environments with extreme temperature variations. |

| Ease of Machining | Can be easily machined into complex shapes with high precision. | Reduces production time and costs in manufacturing processes. |

| Low Friction | Low coefficient of friction makes it ideal for moving parts, reducing wear and energy loss. | Commonly used in gears, bearings, and sliding applications. |

| UV Sensitivity | Can degrade under prolonged UV exposure, limiting outdoor applications without treatment. | Requires protective coatings for outdoor use to enhance longevity. |

| Customization Options | Available in various grades tailored for specific applications and performance requirements. | Allows for tailored solutions in design and production. |

| High-Volume Production | Injection molding capabilities support high-volume, consistent quality production. | Beneficial for manufacturers looking to scale efficiently. |

| Innovative Applications | Used in emerging fields like 3D printing, robotics, and aerospace components. | Expands the scope for new product development and technological advancements. |

In summary, Delrin is a remarkable high-performance plastic with unique properties that make it suitable for a wide array of applications. Its strength, flexibility, and ease of machining have made it a preferred choice across industries, including automotive, electronics, and medical devices. Understanding what Delrin is, its composition, and how it compares to other plastics can help you make informed decisions for your projects.

Whether you’re involved in manufacturing, engineering, or design, recognizing Delrin’s capabilities opens up new possibilities for innovative solutions. By choosing the right grade and properly maintaining Delrin products, you can harness its benefits for long-lasting performance. As technology evolves, Delrin’s potential uses continue to expand, making it a material worth considering for future projects.